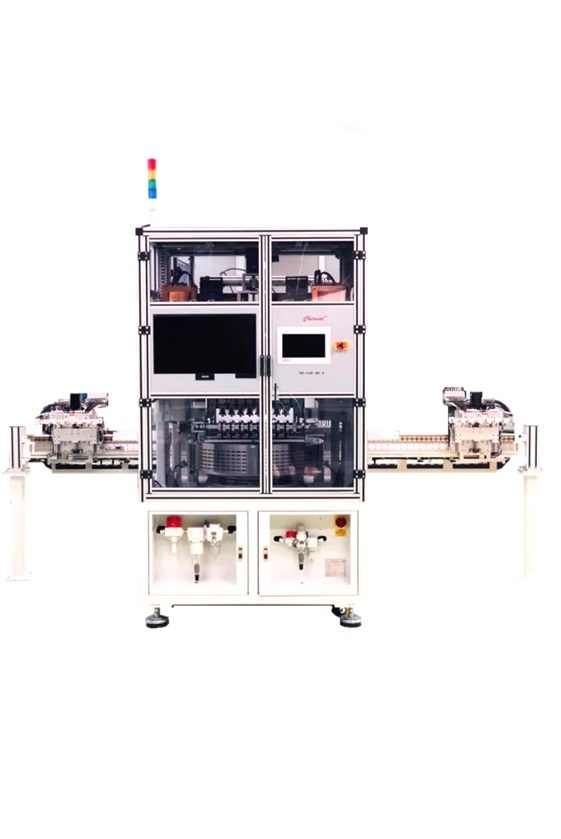

TM-110P-8H-A, Auto Final Bond Machine, is designed for automatic final bonding Flex onto Flex/PCB. All FPCs must be pre-tacked onto Flex/PCB with PSA/TSA/ACF adhesive prior to final bonding. The equipment is equipped with 8 hot heads, which can perform the bonding process on 8 products at the same time, which improves the production efficiency. Each pressure head is controlled by an independent high-precision intelligent control system to ensure rapid heating and the accuracy and repeatability of the heating temperature.